HIGHLIGHTS

Purpose and Values

Montevarchi garden-factory offers to artisan shoemakers a working environment where production spaces harmonize with the outdoors.

In this facility houses the prototyping activity dedicated to Prada women’s footwear, as well as the Linea Rossa and Car Shoe collections.

Montevarchi produces about 700 pairs of shoes every day.

It all begins with prototyping. The samples conceived by the creative office are examined and translated into technical drawings.

Subsequently, the drawing is transferred to model making, which reproduces it on the mold of the shoe, previously covered with a dedicated adhesive paper. This high-precision activity is performed manually or with digital support.

The designed paper is carefully removed from the mold and laid out on a cardboard as a first sketch of the style, from which all the parts that will make up the finished product are obtained.

Single components are cut and inserted in a chart accompanied by a technical data sheet with all the product information: color and type of leather, necessary thread, structure components, such as sole and heel.

The laboratory stages follow the model making steps.

The first one is the manual or machine cutting of the material of the shoe.

The binding operations follow. After the thickness of every component has been uniformed, each part is manually assembled or machine-sewn.

This process results in the upper, the top part of the shoe, carefully developed by the patternmaker before the lasting phase.

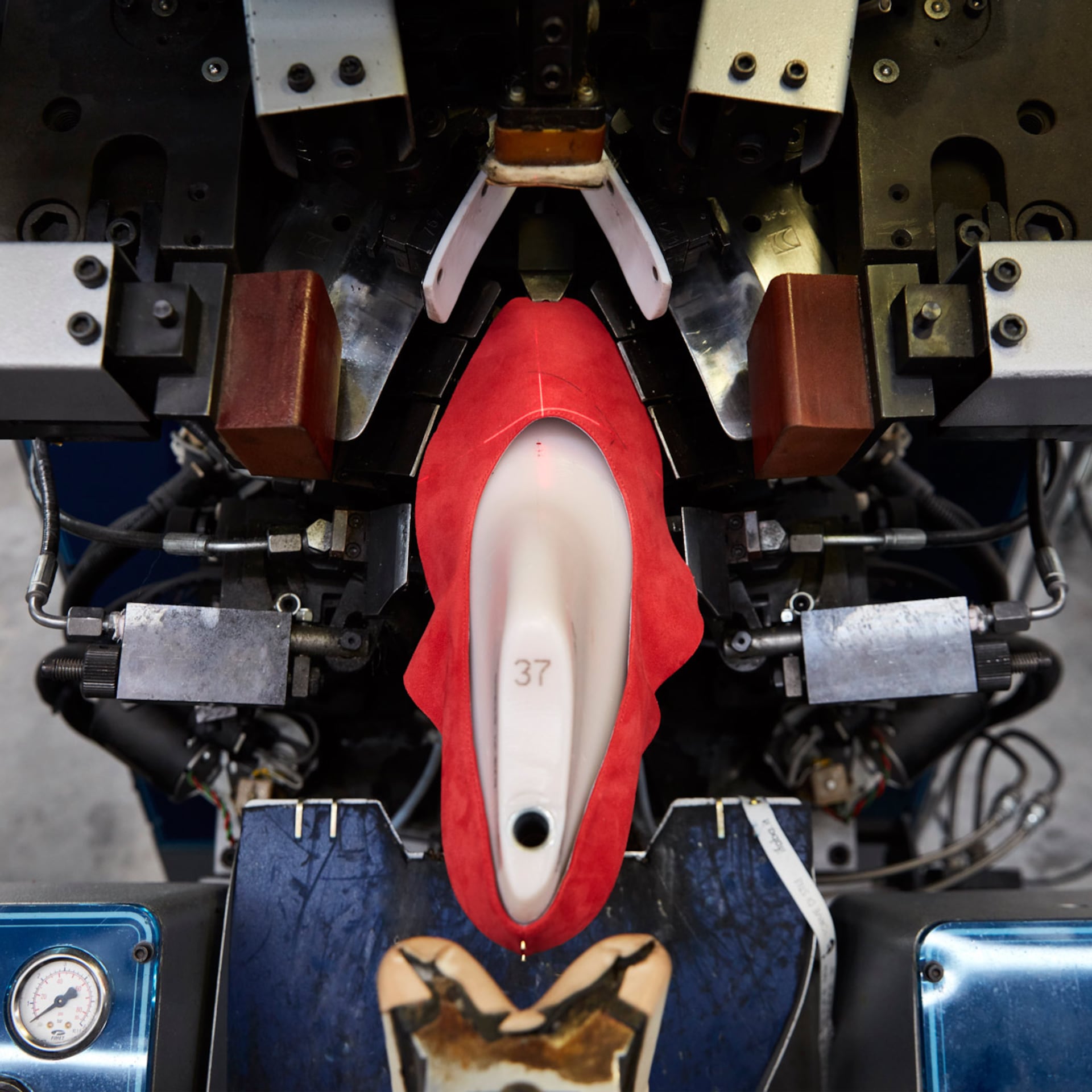

The upper and the other parts of the shoe are loaded on a conveyer belt, leading to the finalization of the shoe, completed with the support of dedicated machinery.

The manual skills of craftsmen remain, however, the most essential element in the manufacturing of the product, as demonstrated by the manual attachment of the upper in the old shoemaker’s fashion.

The upper is then finished on the mold and, finally results in the final prototype, optimized for production.

Hand-pleated fabric covered shoe tip